Building Name: Technology and Engineering Development (TED) Building

Location: 12000 Jefferson Ave, Newport News, VA 23607

Site: The Thomas Jefferson National Accelerator Facility (Jefferson Lab)

Building Occupant Name: Jefferson Lab

Occupancy Classification: Nonseperated Mixed Use Group B (Office) and F-1 (Factory Industrial, Moderate Hazard)

Size: 70,000 SF

Stories Above Grade: Two

Primary Project Team:

Owner: The Thomas Jefferson National Accelerator Facility (Jefferson Lab)

General Contractor / Construction Manager (CMGC): Mortenson Construction

Architects, Engineers, Interior Designers: EwingCole

Cost Estimate Consultant: Crawford Consulting Services, Inc.

Dates of Construction: 8/4/2010 – 9/30/2011

Cost: $16 million – Does not include overhead, fees, insurance, or tax.

Project Delivery Method: Design-Bid-Build

Architecture:

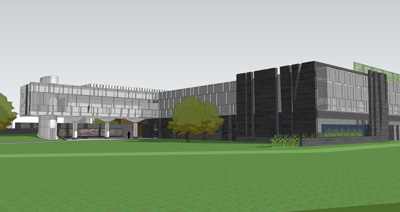

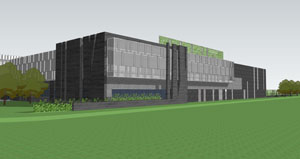

The TED represents the new construction component of Jefferson Lab’s Technology and Engineering Development Facility (TEDF) project. The overall goal of this project is to modernize and optimize the flow of ideas and materials throughout the facility, allowing Jefferson Lab to more efficiently advance research efforts in the area of nuclear physics. Additional components of the project, but not in the scope of this thesis, include the demolition of temporary work spaces and a renovation and addition to the existing test lab (Building 58).

The TED will provide technical workshop, fabrication, and office spaces for the engineering departments of electrical, mechanical, cryo fabrication, vacuum and installation, and the physics division. The first floor is split into two “bay” areas. The low bay (12’ clear) areas give technical workspaces and storage to electrical, cryo fab, vacuum, and physics while a high bay (20’ clear) area houses a 10-ton crane, welding shops, and assembly areas for cryo fab, vacuum, electrical, and physics. The second floor provides office space, conference rooms, libraries, a café, and a fitness center. Most of the office space is open, with few fully enclosed offices. This not only creates an atmosphere that encourages collaboration, but it also allows light to penetrate deep into the space.

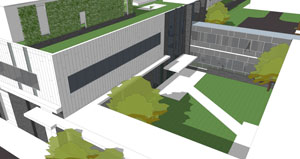

Located to the west and adjacent to Building 58, the TED will provide more services to the facility than its interior technical and office programs alone. It will improve the image of the facility from the main entrance driveway, institute a common entrance to be shared by Building 58, and provide efficient service yard space. The common entrance, located at the north end of the building, is accentuated by a second floor overhang that creates an inviting space for employees and visitors. Two corridors will connect the TED to Building 58, primarily allowing efficient transportation of ideas and materials. However, these corridors also complete the enclosure of an outdoor courtyard between the TED and Building 58, further inducing gathering and collaboration between scientists and engineers.

Applicable Codes and Zoning:

- Virginia Construction Code 2006, (based on the 2006 edition of the International Building Code)

- Virginia Rehabilitation Code 2006 (based on the 2006 edition of the International Existing Building Code)

- Virginia Plumbing Code 2006 (based on the 2006 edition of the International Plumbing Code)

- Virginia Mechanical Code 2006 (based on the 2006 edition of the International Mechanical Code)

- Virginia Fuel Gas Code 2006 (based on the 2006 edition of the International Fuel Gas Code)

- Virginia Energy Conservation Code 2006 (based on the 2006 edition of the International Energy Conservation Code)

- Virginia Statewide Fire Prevention Code 2006, (based on the 2006 International FireCode)

- Virginia Industrialized Building Safety Regulations 2006

- NFPA 101®, The Life Safety Code®, 2006 edition (LSC)

- DOE STD-1066-99 Fire Protection Design Criteria

- Factory Mutual Loss Prevention Data Sheets –as referenced by DOE STD-1066-99

Historical Requirements:

None to be discussed.

Enclosure:

The façade includes precisely machined metal, glass, and masonry materials that communicate the technicality of the interior program to the exterior. The areas of the first floor façade exposed away from Building 58 or exposed to the courtyard is primarily composed of varying styles of brick veneer on CMU backup. The areas of the first floor façade exposed to the service yard or Building 58 is composed of groundface CMU and is an extension of the foundation wall. The second floor façade exposed away from Building 58, enclosing the open office area, utilizes a curtain wall system that contains custom fritted glass. Other areas of the second floor façade exhibit insulated aluminum panels. The exterior portion of the façade enclosing the two-story high bay is comprised mainly of brick veneer with curtain wall system accents.

The roofing membrane is an off-white, Ethylene Interpolymer (KEE) Roofing material. This membrane is energy star rated with a solar reflective index (SRI) of 98.54. This membrane lies atop 5/8” protection board, R-30 rigid insulation, metal deck; all are supported by structural steel.

Sustainability:

The TED utilizes two important mechanical sustainable features. First, a closed-loop, vertical-bore geothermal heat pump system provides the primary amount of chilled and hot water used for the mechanical systems. Second, each of the two air handling units is coupled with an energy recovery unit to precondition incoming outdoor air, providing free heating or cooling.

An efficient use of daylight is used on the second floor due to the combination of an open office plan and the amount of exterior glazing. Natural light is allowed to penetrate deep into the office space, minimizing the need for artificial lighting.

Various programs are planned to educate employees and visitors about green building features. These programs include the use of signage to emphasize sustainable components, the use of strategically placed windows to view sustainable mechanical equipment, and educational tours given through the facility for visitors.

Other features include:

- Rainwater Collection

- Water use reduction

- Use of recycled materials

- Use of low-emitting materials

- Heat island effect reduction

- Encouragement of alternative transportation

These mentioned sustainable efforts, in addition to countless others, qualify the TED to receive a LEED-NC Version 2.2 GOLD certification.

Construction:

The Jlab Management and Operating Contractor, part of Jefferson Science Associates, LLC, with the oversight and funding of the US Department of Energy is managing one fixed-price contract with the A/E firm and one fixed-price contract with the CM/GC. The CM/GC contract was awarded through a design-bid-build process and contains two phases. The first phase is for the CM/GC to assist and support the A/E firm during the final stage of design, while the second phase is to carry out the construction and completion of the project.

The total cost of the TEDF project is projected to be $73.2 million, with project initiation starting in September 2007, general construction starting in August 2010, and the scheduled start of operations on March 2014.

The 70,000 SF TED will cost approximately $16 million with construction beginning in August 2010 and completing in September 2011.

Mechanical System:

Two 32,000 CFM air handing units supply 55ºF air to variable air volume boxes, serving interior zones, and series fan powered boxes, serving perimeter zones. These boxes each contain a reheat coil. AHU-1 serves the first floor and high bay areas, while AHU-2 serves the second floor. Each AHU contains a mixing box for recirculated air, a MERV 8/13 filter assembly, a preheat coil, a cooling coil and is connected to a dedicated outdoor air preconditioning unit, sized for 10,000 CFM. These preconditioning units contain an enthalpy wheel that exchanges energy between building exhaust air and incoming outdoor air without mixing the flows. The quantity of outdoor air is determined by the quantity of exhaust make-up, pressurization, or occupancy ventilation determined by ASHRAE Std. 62.1-2007.

The 2000 MBH of heating and 215 tons of cooling are provided by a hybrid closed loop geothermal heat pump system that includes a 75 ton closed circuit cooling tower, which is used to offset peak loads. The geothermal well field is comprised of 192 total vertical wells running in a reverse return configuration. They are 275 ft deep and separated at 18 inches on center. The total number of wells is divided into three fields of 64 wells that are connected in a valve vault located close to the building. The condenser water running through these wells is maintained between 50ºF (heating) and 90ºF (cooling).

A total of twelve water to water heat pumps use the hybrid geothermal system to create 44ºF chilled water and 120ºF hot water that supply the air handling units and terminal unit reheat coils. Additionally, a gas fired condensing boiler is available incase of heat pump failure and to prevent freezing in the condenser system. Seven heat pumps are dedicated to chilled water production, two heat pumps are dedicated to hot water production, and the remaining three can produce either hot or cold water, depending on the load.

Additional space conditioning equipment includes three 1.5 ton, wall mounted, water-cooled air conditioning units and two 60 MBH cabinet unit heaters. The water-cooled air conditioning units, located in three server and data rooms, are supplied with geothermal system condenser water and the two cabinet unit heaters, located in vestibules, are supplied with hot water.

The building automation system is DDC controlled and connected to the rest of the campus via a LAN Ethernet network. Variable frequencies drives are used for air handling unit supply and return fans, and condenser water, chilled water, and hot water circulation pumps.

Electrical System:

A Dominion Power substation provides 22 MVA to the Jefferson Lab campus. The TED draws its power from a 15 kV rated switchgear lineup connected to the 22MVA substation. A pad mounted liquid-filled transformer rated at 2500 kVA steps the voltage down from 12.47 kV (primary) to 480/277V (secondary) before connecting to the main switchboard. The switchboard will serve lighting, power distribution, and dedicated mechanical equipment panels in addition to providing normal power to life-safety and mission critical automatic transfer switches.

A 100 kW/125 kVA generator will provide back-up power to a life-safety automatic transfer switch and a mission critical automatic transfer switch. The 100 A life-safety ATS serves panels containing emergency and egress lighting, elevator controls and lighting, fire alarms, telecommunications, access control systems, and oxygen/refrigerant monitoring systems loads. The 260 A mission critical ATS serves various mechanical equipment pumps, fume hoods, exhaust fans and has room for other critical loads to be determined by Jefferson Lab personnel.

Lighting System:

T-5 fluorescent lamps are used as the primary lighting source in the first floor lab areas and second floor open office areas, providing average illuminations of 75 and 30 Footcandles respectively. Task lighting is accomplished by plug-in LED fixtures. Lighting in the high-bay is accomplished by the use T-5 HO fluorescent lamps and provide an average illumination of 50 Footcandles.

All lighting panel boards are connected to individual motor-controlled circuit breakers that will be set to a schedule by Jefferson Lab personnel in order to cut down on energy usage. In addition, photocells are placed in the second floor office area to detect the amount of natural light entering the space. If a certain amount of natural light is detected, a signal will be sent to the lighting control system to turn off the perimeter lights in the space. A time delay is included to keep from constant switching when natural light levels are close to the limit.

Structural System:

The foundation of the TED is rooted in the ground using 35’ deep piles with a diameter of 16” and a compressible strength of 40 tons. The foundation system is comprised of shallow spread footings and continuous footings with a capacity of 2000 psf. A continuous wall footing surrounds the exterior of the building, supporting the exterior wall. The high bay floor is a 10” thick normal weight concrete slab while the rest of the TED floor is a 5” thick normal weight concrete slab. The second floor office space floor is a 3 ¼” lightweight concrete slab, compressive strength of 3000 psi, with a 2” galvanized metal deck. All foundation concrete has a compressive strength of 4000 psi.

The second floor office space is framed by a system of steel wide flange beams ranging in size from W16x26 to W18x35 connecting to W12 x 53 steel columns. The high bay area is supported vertically through a combination of W10x54 and W14x90 steel columns. The office space roof is supported by a combination of wide flange beams and K-series joists, while the high bay roof is supported using DLH joists spaced 7’-4” on center. The entire roof is a 1 ½” 18 gage galvanized metal deck with a ¼” per foot slope and supports insulation and a roofing membrane as mentioned in a previous section.

Fire Protection System:

The TED has wet pipe automatic sprinklers that comply with flow and coverage areas according to NFPA 13. Dry chemical fire extinguishers are provided in administrative areas, while any area containing sensitive electronics is provided with CO2 extinguishers. The fire detection system is made up of photoelectric room and duct smoke detectors, heat detectors, and manual pull stations. Processes that occur when an alarm is tripped include logging the tripped device at the main alarm panel, activating the audio and visual alarm systems, shutting down air handler supply/return fans, and closing smoke dampers as necessary.

Telecommunication System:

The overall architecture of the telecommunications system utilizes a star topology, where all points, such as local telecom closets, on the network are connected directly to a main distribution frame, which will be located in the test lab addition. Each administrative workstation, such as those in offices and conference rooms, has a 3-position outlet containing three RJ-45 jacks; two available for data and one available for voice. Laboratory workstations are outfitted with 2-position RJ-45 jacks. LAN Ethernet connections utilize fiber-optic cabling while voice cabling is unshielded twisted pair copper cabling.

Transportation:

One hydraulic passenger elevator is located in the entrance lobby at the center of the building. Two stairways serving the second floor lead directly to exits. One is located at the north end of the building by the entrance overhang, and the other is located at the south end of the by the high bay area. A third, open, stairwell is located next to the elevator, however, does not lead directly to an exit.

Access Control:

An access control system will be put in place that will connect to the existing campus system. Card access will be required primarily at exterior entrances to the building. All card readers will report back to a main CPU, where logs will be kept and hard copies printed. The main CPU will also monitor the card readers and signal alarms if a card reader failure is detected. |